WMF 0413160011 Lono Te och Vattenkokare 2-i-1 Glas 1,7l XXL-Tesil 4 Temperaturnivåer LC-Skärm 3000 W : Amazon.se: Hem & kök

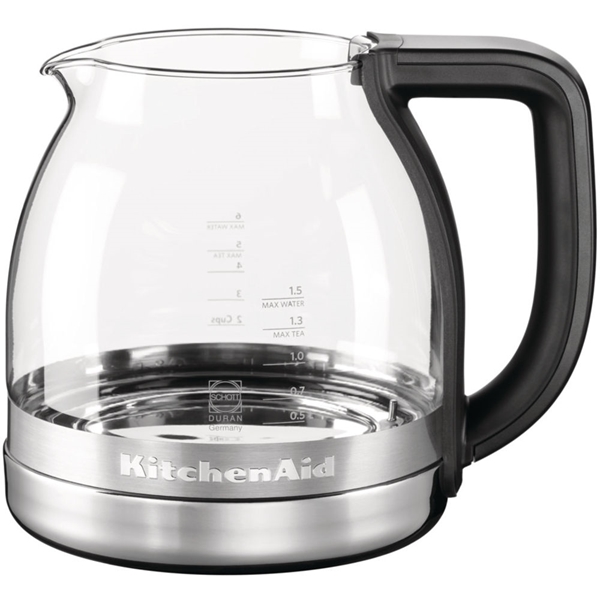

XAVION vattenkokare, 2 400 watt, LED-belysning, skott Duran märkglas, 1,7 liter, utan snöre, 10877 : Amazon.se: Home & Kitchen

Gastroback 42438 Design Tea and More Advanced automatisk tekokare och vattenkokare, multifunktionskokare : Amazon.se: Hem & kök

Severin WK 3479 Vattenkokare sladdlös, Överhettningsskydd Glas, Rostfritt stål (borstat), Svart | Conrad.se

XAVION vattenkokare, 2 400 watt, LED-belysning, skott Duran märkglas, 1,7 liter, utan snöre, 10877 : Amazon.se: Home & Kitchen