Signes de toilettes - signe de toilettes publiques, signes de papier peint • papiers peints quelques, reste, corps | myloview.fr

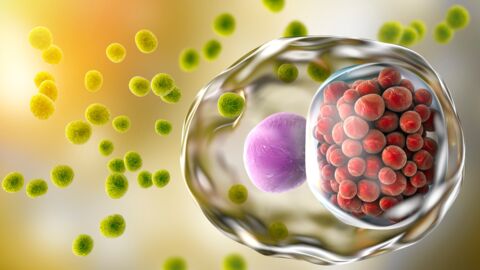

Bactéries : quelles maladies est-on susceptible de contracter aux toilettes ? : Femme Actuelle Le MAG

Non, vous épiler le maillot ne vous expose pas plus aux infections sexuellement transmissibles — Queen MAFA